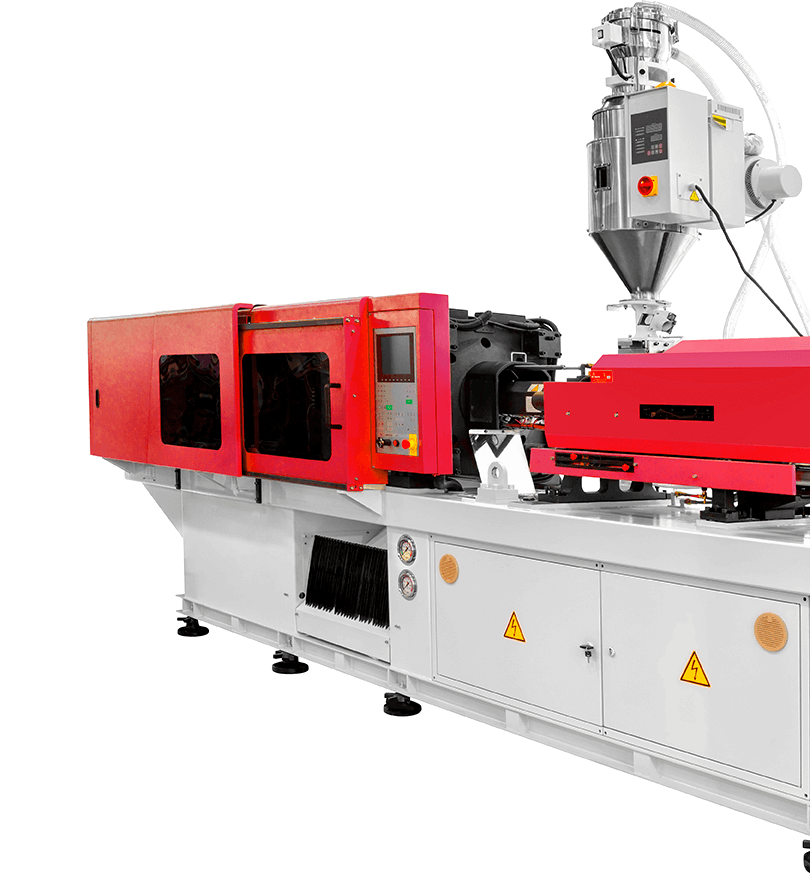

One of the most common methods of converting plastics from the raw material form to an article of use is the process of injection molding. This process is most typically used for thermoplastic materials which may be successively melted, reshaped and cooled. This versatile process allows us to produce high quality, simple or complex components. Injection molding consists of a high pressure injection of the raw material into a mold cavity which shapes the polymer into the desired shape.

Injection Molding

Services

|

Key Advantages & Benefits

of Molding Parts with injection molding:

|

Got a Question?

Talk to Us!