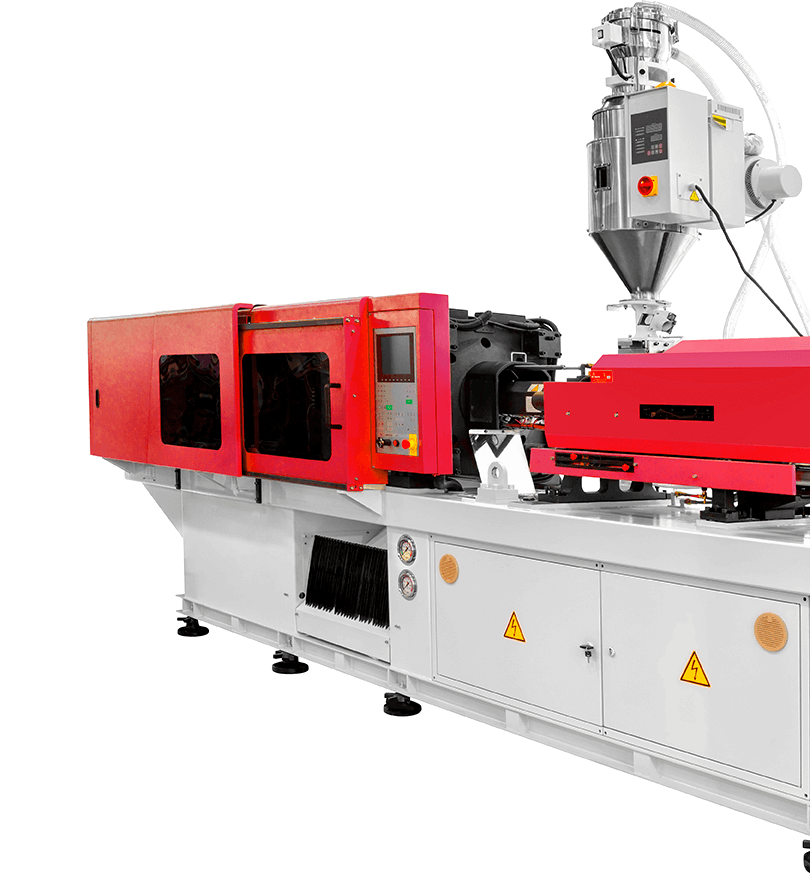

PPI is an ISO 9001:2015 and Underwriters Laboratories certified facility. Our number one priority is Total Quality, by achieving consistent part quality and customer satisfaction we are a preferred dock-to-stock supplier.

Our dedication to quality enables us to operate efficiently and accurately, and in compliance with the ISO 9001:2015 standard. Our Quality Department coupled with our state-of-the-art equipment is staffed with qualified inspectors with decades of experience.

OUR QUALITY SERVICES INCLUDE:

- Quality Assurance is ISO 9001-2015 Certified by Perry Johnson Registrar

- Accuracy and repeatability in dimensional measurement and geometric characteristics

- Statistical data analysis and decision making

- Color accuracy and repeatability capability through the use of spectrophotometer readings

- Moisture analysis of hygroscopic materials

- Underwriter Laboratories recognized molder and applicator

- IQMS/ ERP / Plant Management Software System

- Standridge 36×72 surface plate, 2 36×48 surface plates

- Minolta CM-700d Spectrophotometer

- BK Gardner Gloss Meter

- IMS Dew-Temp Dryer Monitor

- Ishida Weigh Scales