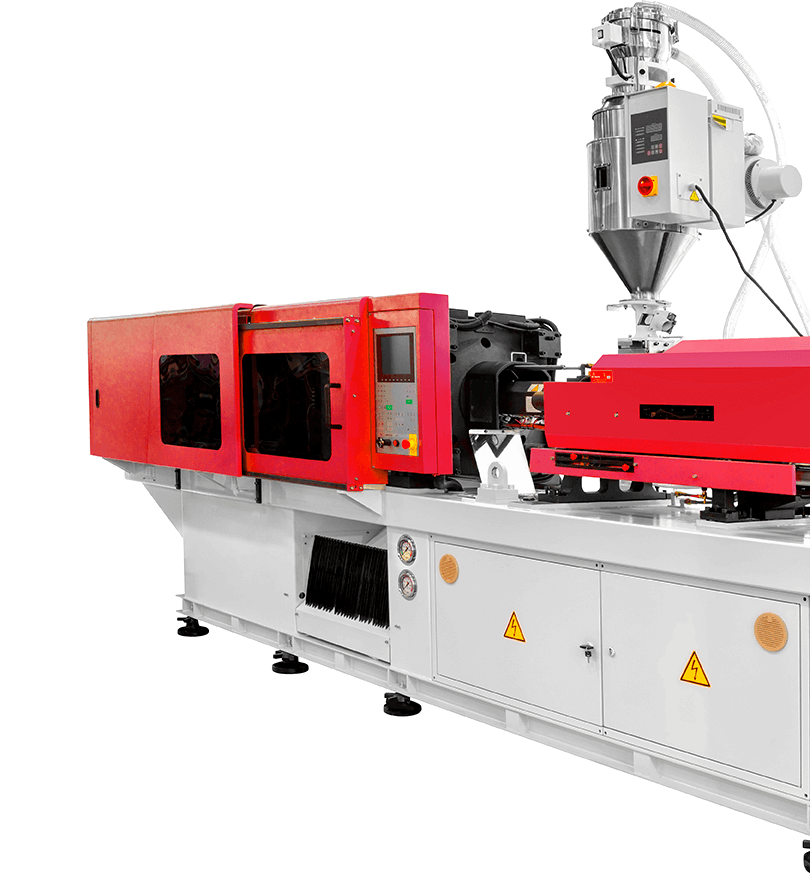

Gas-Assisted Injection Molding is a process where an inert gas is introduced at pressure, into the polymer melt stream at the end of the polymer injection phase. The gas injection displaces the molten polymer core ahead of the gas, into the as yet unfilled sections of the mold, and compensates for the effects of volumetric shrinkage, thus completing the filling and packing phases of the cycle and producing a hollow part.

Key Advantages & Benefits

of the Gas Assist Process:

- Increased design flexibility – combines strength of structural foam with cosmetics of injection molding, allowing multiple features designed right into your parts.